Solution

- home

- Solution

- Biological wastewater treatment

Biological wastewater treatment

Complete control over water quality measurements affecting the environment.

Sustainable Biological Wastewater Treatment Solutions

Biomax's biological wastewater treatment solution provides complete control over the water quality measurements that affect the environment.

It can increase the activity of living bacteria and effectively remove harmful substances such as T-N and TOC.

Industrial wastewater treatment

slaughterhouses, leather processing, mining, etc. Typically, these processes deal with high concentrations of organic matter that require biological treatment.

Most sewage and wastewater have a BOD of 175-250 ppm, while industrial wastewater has a BOD of 500-10,000 ppm, and even higher.

Chemical waste

It breaks down common industrial chemicals containing phenols, alcohols, alcohols, alcohols, and aromatic compounds.

Confectionery and candy process

It perfectly handles chocolate processing-related chemical, liquid sugar (syrup), fructose and sugar waste.

Dairy processing process

It successfully treats wastewater such as oil and fat, which are wastes generated from milk and cheese processing.

Detergent process

You can remove most of the regular detergent components and surfactants.

Fish processing process

It breaks down nitrogen compounds in wastewater, fish processing by-products, and organic compounds in fish waste.

Food processing process

Numerous food processing plants use it to remove BOD and odors.

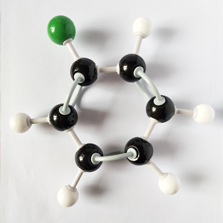

Halogenated Aromatic Process

Numerous halogenated aromatic wastewater, including chlorophenol and dichlorophenol, are degraded by Aquapmo-Aquabc.

Nitrification process

AQUAPMO AQUBAC has nitrosomonas and nitrobacter, which can denitrate organic matter because nitrates are reduced after nitrification.

Paper and Cellulose Processing

It is used in the paper industry to reduce BOD and remove odors, and acts as a cellulose dissociation promoter, which can improve the product's ability to remove fillers other than fiber.

Pharmaceutical process

AQUAPMO AQUBAC can be used as a medium for the majority of fermentation, as well as as as an extraction solvent. It can also be used as a binder in the process of making pills.

Oil refinery waste

It is used to treat the majority of oil wastewater with many problems such as phenol, ammonia, hydrogen sulfide, oil, and grease.

Steel manufacturing process

It is used to remove phenols, cyanides, and ammonia commonly found in smoke-making processes or to treat oils used in steel rolling processes.

Tanning process

It is widely used for wastewater treatment involving vegetable tanning, except for the chromium tanning process. It can treat oils, fats, ammonia, and proteins from both processes, but not hexavalent chromium from chromium tanning process wastewater.

Textile processing process

It treats organic dyes used in textile processing plants, some surfactants, and starch for sizing, enabling the bleaching of some wastewater.

However, ingredients related to inorganic dyes cannot be processed.

Casting process (wine/alcohol)

It is used to treat alcohol, tannic acid, and sugars found in casting wastewater.

It alleviates the thickening of wastewater caused by the formation of polysaccharides in the wastewater.

Beverage manufacturing process

It treats sweeteners, fructose and liquid sugars used by soda manufacturers in the beverage manufacturing process.

AQUAPMO AQUBAC is used to remove most of the above standard processes and mainly BOD, COD, ammonia, hydrogen sulfide, nitrate, and a limited range of metals.

Depending on the existence of hard-to-break substances and the stability of the system, the administration method for industrial wastewater may require a larger amount.

biological wastewater treatment process

BOD + N + P + O2 → CO2 ↑ + H2O + Cells dissolved organic matter is expressed as BOD.

Nitrogen (N), which is important for protein synthesis, and phosphorus (P), which is required for energy transfer, are accumulated in the body of bacteria, and when organic substances are not sufficient as food for bacteria, the following digestion process occurs.

Cells + O2 → CO2 ↑ + H2O + N + P sludge In batch systems such as pit or reservoir, bacteria breathe internally as they grow, which emits carbon dioxide and leaves only minerals in the water.

The use of microbe-grisim will not only survive the system's activity but also significantly improve the system's BOD removal efficiency, and will also remove an additional 15 to 40% of the existing active sludge production with additional benefits.

The administration of microbe-grissim results in a greater number of dynamic microbial growths, which decomposes what is loaded on the system faster, lowers the F/M average, and reduces the BOD runoff concentration.

Comparing the two outcomes carried out under the same climate and conditions, it is easy to see.

| Duration of pressing Press-cake(Time) |

Volume of Raw sludge(Tons) | TSS of Press-cake(tons) |

|---|---|---|

| 97. 7. 28 ~ 8. 7 | 2,083 | 270.18 |

| 98. 7. 27 ~ 8. 1 | 1,330 | 178.12 |

| 차이 (-2 days) | - 753 | - 92.06 |

| (36.25%) | (34.10%) |

After Aquapmo-Aqubac administration, 36% of sludge and 34% of solids were reduced.